Solubility is one of the key attributes of a drug candidate and one of the biggest challenges in drug development. Approximately 70-90% of New Molecular Entities (NMEs) in today’s drug pipeline are poorly soluble, which complicates delivery, resulting in poor bioavailability. The majority of these NMEs are DCS Class IIa / IIb and IV, which exhibit low bioavailability due to solubility-limited (IIb) absorption, dissolution rate-limited (IIa) absorption, or permeability limitations (IV).

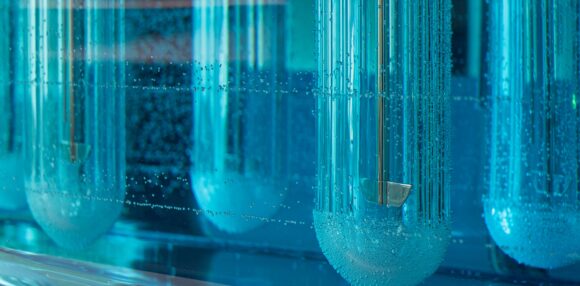

Our Early Phase Drug Product Innovation Centre of Excellence can formulate NMEs with challenging properties – such as peptides and small molecules with limited solubility, permeability, very low drug load, high potency, and limited stability – into Oral Solid Dose drug products. Our enabling technologies such as spray drying, hot melt extrusion, nanomilling, and micronization solve solubility-induced absorption issues.

For peptides or large molecules that exhibit limited bioavailability caused by poor permeability through the intestinal barrier, lipid-based formulations (e.g. SEDDS / SMEDDS, sLNP, Cochleates) or permeation enhancer-based formulation technologies are required. To address these challenging APIs, we apply innovative formulation approaches to provide prototypes for animal in vivo investigations for oral peptide delivery. All formulations can be manufactured as a solid form, allowing for larger production scale.

Oral Solid Dose

Our three facilities focused on the development and manufacture of oral solid dosage forms have capabilities in conventional processing technologies (wet and dry granulation, fluid bed) for tablets (standard, minitablets) and capsules (direct API, powders, pellets, minitablets), including aesthetic and enteric coating.

Want to find out more?

Get in touch with our team of experts to explore bespoke end-to-end CDMO support of your complete drug lifecycle

at any scale.